10038 Street No:1 AOSB 35620 Cigli / Izmir

10038 Street No:1 AOSB 35620 Cigli / Izmir

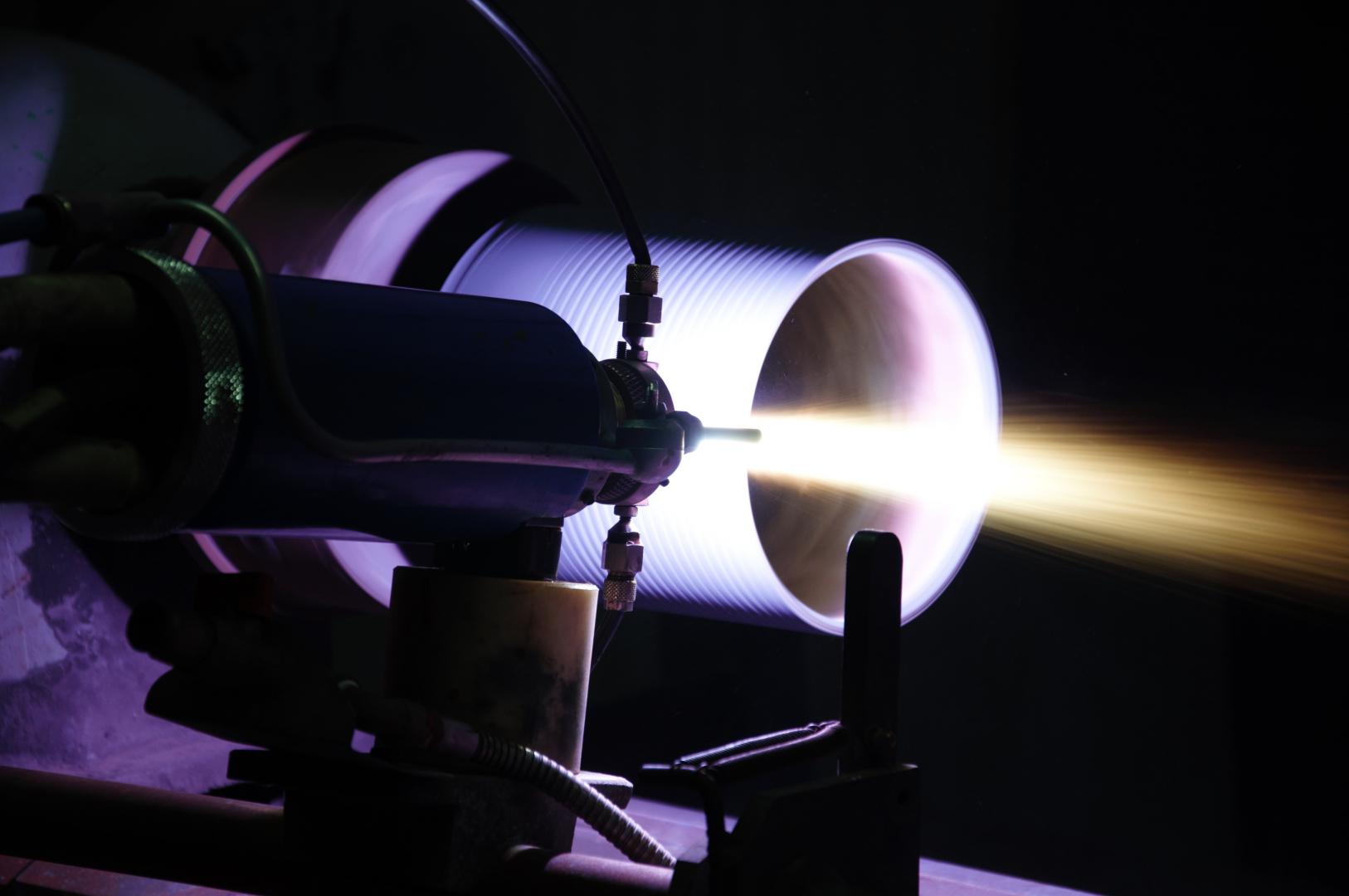

Thermal spray coating is a

process that sprays coating materials using the pressure of a high-heat gas.

The material then bonds to the surface, forming a coating that grants

properties such as corrosion protection, thermal resistance, environmental

protection, lubricity, wear resistance, and electrical/thermal conductivity.

In today's industrial

settings, it is common for components to face challenging environments that

cause them to wear down, erode, get scratched, or corrode over time. To protect

these parts and extend their lifespan, they require coatings that act as a

shield. There are various methods available for applying coatings, but thermal

spray coating has gained significant popularity due to its speed and

versatility. It is chosen because it allows for the quick application of

coatings while offering flexibility in terms of the materials that can be used.

DEKA is dedicated to offer the

best technical surface solutions in the industry for most components and parts.

And the ultimate result lies in choosing the best combination of the coating

technology and the composition of the coating powders.

Every application has to be

analyzed for proper function, operating conditions, and technical requirements.

It is important to analyze these conditions before coming up with the ideal

substance of the body itself and the best alloy of the coating to be applied.

This is what DEKA has done for many years.

Each body shape and structure

has to be produced according to the correct specifications received from the

customer; since it is very important to be able to control the entire

manufacturing process from start to finish. DEKA, therefore, produces all parts

in-house, starting from the raw material up to the final finishing. All parts

are manufactured by DEKA in-house and shipped directly to its customers.

DEKA always analyzes the

working condition of the parts and offers the ultimate material for a wide

range of coatings for metals that are ferrous and non-ferrous.

To ensure the quality of the

coating, one of the most important steps is surface preparation. A

well-prepared surface is essential to obtain a good bonding quality between the

substrate and the coating.